| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : OURUIDA

Model Number : MF-300KW+200KG

Certification : CE ,ISO, ROHS,GSG EU

Place of Origin : CHINA

MOQ : 1set

Price : Negotiation

Payment Terms : L/C, D/P, T/T, D/A, Western Union

Supply Ability : 1000SETS /Month

Delivery Time : 5-15DAYS

Packaging Details : Export Wooden box Packaging

Product name : Medium Frquency Induction melting furnace machine

Power : 300KG

Voltage : 3phase 340V-480V

Cooling system : Water cooling system

Industrial test reports : Provided

Melting capacity : 200KG

smelt material : Steel, aluminum, stainless steel, copper, iron

Smelting Frquency : 1-20HKZ

CE And ROHS Manufacturer Supply Medium Frquency Induction melting machine with 200KG Melting furnace:

About Induction heating machine :

Induction heating is a process which is used to bond, harden or soften metals or other conductive materials. For modern manufacturing processes, induction heating offers an attractive combination of speed, consistency, control and energy efficiency.

The basic principles of induction heating have been understood and applied to manufacturing since the 1920s. During World War II, the technology developed rapidly to meet urgent wartime requirements for a fast, reliable process to harden metal engine parts.

More recently, the focus on lean manufacturing techniques and emphasis on improved quality control have led to a rediscovery of induction technology, along with the development of precisely controlled, all solid state induction power supplies.

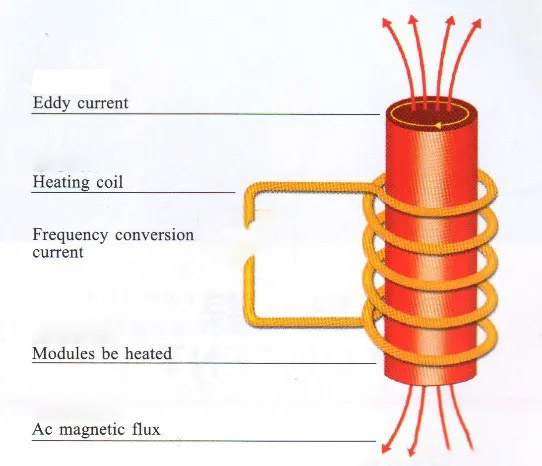

How induction heating works?

When an alternating electrical current is applied to the primary of a transformer, an alternating magnetic field is created. According to Faraday’s Law, if the secondary of the transformer is located within the magnetic field, an electric current will be induced.

In a basic induction heating setup, a power supply sends an AC current through an inductor (often a copper coil), and the part to be heated (the workpiece) is placed inside the inductor. The inductor serves as the transformer primary and the part to be heated becomes a short circuit secondary. When a metal part is placed within the inductor and enters the magnetic field, circulating eddy currents are induced within the part.

Induction melting furnace equipment photos :

Fetures:

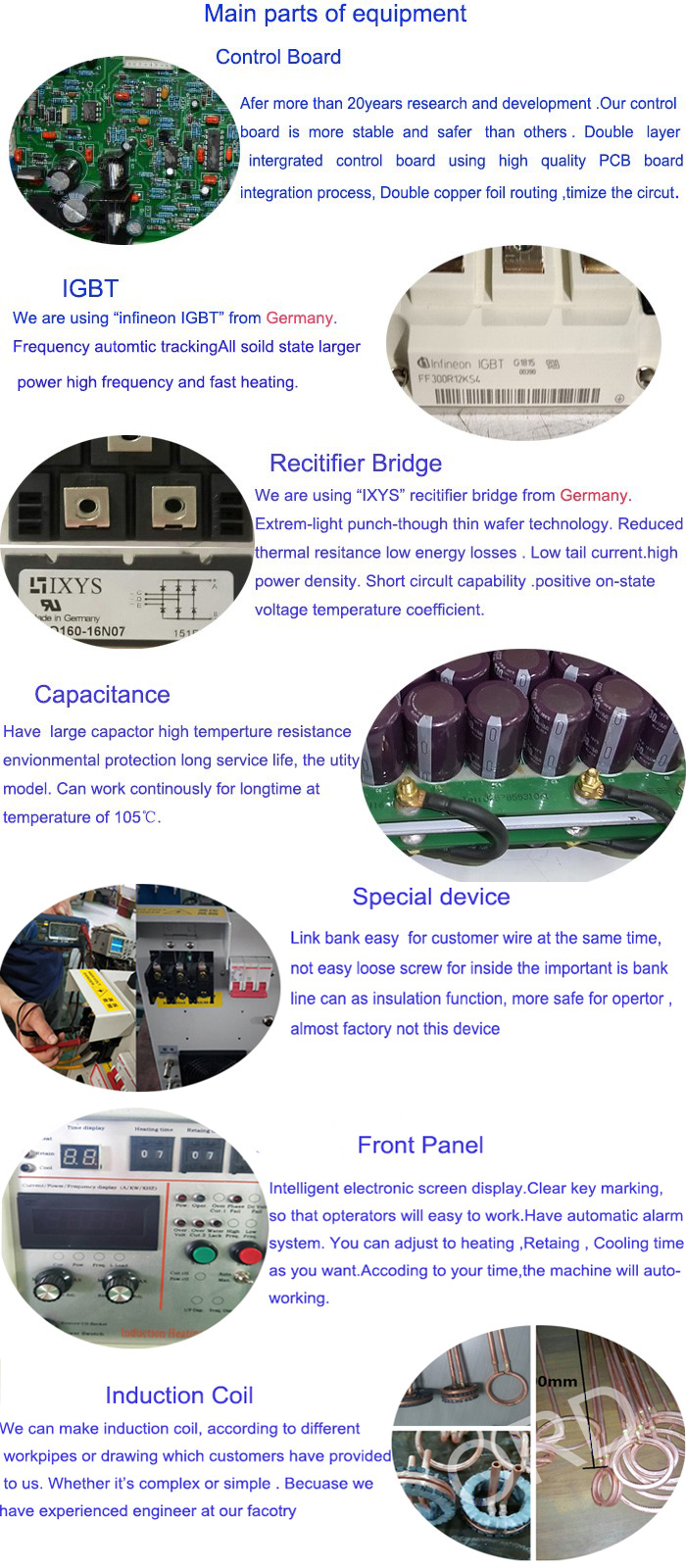

1. Adopts all-solid-state power conversion module Siemens IGBT technology.

2. With full range of protection features such as: over-current, water shortages, overheating, over-voltage, short circuit, lack of protection, greatly improving the reliability of the equipment and convenient equipment maintenance.

3. Portable, Small, space-saving,light weight,eacy to move.

4. No need debug, After connectting through electrical&water can be used.

5. Easy operation, suitable for factory, family, institute & Laboratory smelting experiments

6. Can melt various kinds of metals.

7. 24 hours continuous smelting capacity.

Melting metal meterials : steel, stainless steel, iron, copper, aluminum, aluminum alloy, gold, silver.

| Type | MF-300KW -200KG |

| Work Power | 3*380v/415v/440v/480v 50-60hz |

| The range of operating voltage | 340-430V AC |

| Output power | 300KW |

| Input current | 450A |

| Capacity | 200KG |

| Work temperature | 0-1850ºC |

| Melting time | fast |

| Fluctuating frequency | 1-20khz |

| Timing (Heat time,Retain time,Cool time) | 1-99S |

| Cooling system | water cooling |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

|

|

CE And ROHS Medium Frequency Induction Melting Machine With 200KG Furnace Images |